Physical Address

304 North Cardinal St.

Dorchester Center, MA 02124

Physical Address

304 North Cardinal St.

Dorchester Center, MA 02124

Technology reporter

Sierra space

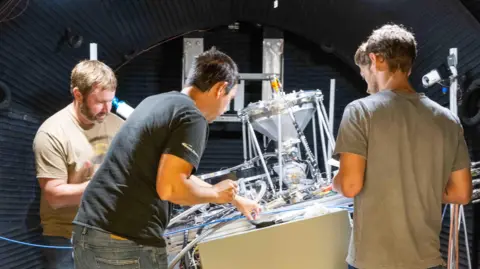

Sierra spaceWithin a giant sphere, engineers thoroughly examined their team. Before them there was a silver metal gadget wrapped in colored cables: a box that they hope that one day will produce oxygen on the moon.

Once the team left the sphere, the experiment began. The cash -shaped machine was now ingesting small amounts of a dusty regolite: a mixture of sharp powder and sand with a chemical composition that mimics the real lunar soil.

Soon, that regolito became a dough. A layer was heated to temperatures above 1,650 ° C. And, with the addition of some reagents, the molecules containing oxygen began to bubble.

“We have tried everything we have been able to so far on Earth,” says Brant White, Sierra Space programs director, a private company. “The next step is to go to the moon.”

Sierra Space experiment was developed at the NASA Johnson Space Center this summer. It is far from being the only technology of this type in which researchers are working, since they develop systems that could supply astronauts who will live in a future lunar base.

These astronauts will need oxygen to breathe, but also to produce fuel for rockets that can be launched from the moon and go to farther destinations, including Mars.

The inhabitants of the lunar bases may also need metal and could even collect it from the gray debris that cover the lunar surface.

It depends on whether we can build reactors capable of extracting those resources effectively or not.

“I could save billions of dollars in mission costs,” says White while explaining that the alternative (carrying a lot of oxygen and replacement metal to the moon from the earth) would be arduous and expensive.

Sierra space

Sierra spaceLuckily, the lunar regolite is full of metal oxides. But while the science of extracting oxygen from metal oxides, for example, it is well understood on earth, doing so on the moon is much more difficult. Especially because of the conditions.

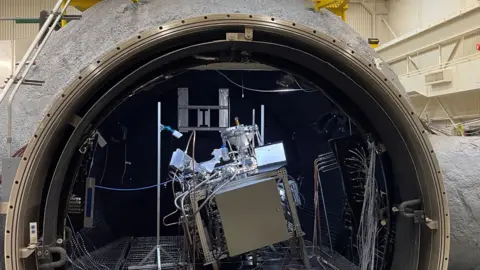

The huge spherical chamber that housed the Sierra Space tests in July and August of this year induced a void and also simulated temperatures and lunar pressures.

The company says that it has had to improve the operation of the machine over time so that it can better face the extremely irregular and abrasive texture of the regolito itself. “It reaches everywhere, wears all kinds of mechanisms,” says White.

And the only and crucial that cannot be proven on earth, not even in orbit around our planet, is lunar gravity, which is approximately a sixth part of the earth. It may not be until 2028 or later that Sierra Space can test your system on the moon, using real regolito under conditions of low gravity.

POT

POTThe gravity of the moon could be a real problem for some oxygen extraction technologies unless engineers designed for it, says Paul Burke from Johns Hopkins University.

In April, he and his colleagues published an article detailing the results of computer simulations that showed how a different process of oxygen extraction could be hindered by the relatively weak gravitational attraction of the moon. The process that is investigated here was the electrolysis of the molten regolite, which implies the use of electricity to divide lunar minerals that contain oxygen, in order to extract oxygen directly.

The problem is that this technology works forming oxygen bubbles on the electrodes surface deep in the molten regolite. “It is the consistency of, let’s say, honey. It is very, very viscous, ”says Dr. Burke.

“Those bubbles will not rise so fast and, in fact, they may take to part with the electrodes.”

There could be ways to avoid this. One could be to vibrate the device of the oxygen producing machine, which could release bubbles.

And the extraordination electrodes could facilitate the detachment of oxygen bubbles. Dr. Burke and his colleagues are now working on ideas like this.

Sierra Space technology, a carbothermal process, is different. In your case, when bubbles that contain oxygen are formed in the regolite, they do it freely, instead of on the surface of an electrode. This means that there is less possibilities that they are stuck, says White.

Highlighting the value of oxygen for future lunar expeditions, Dr. Burke estimates that, per day, an astronaut would need the amount of oxygen contained in approximately two or three kilograms of regolito, depending on his physical condition and his levels of activity.

However, the life support systems of a lunar base would probably recycle the oxygen exhaled by astronauts. If so, it would not be necessary to process so much regolite only to keep lunar residents alive.

The true case of use of oxygen extraction technologies, adds Dr. Burke, is to provide oxidant for rocket fuels, which could allow ambitious space exploration.

MIT and Shaan Jagani

MIT and Shaan JaganiObviously, the more resources be generated on the moon, the better.

The Sierra Space system requires the addition of some carbon, although the company says it can recycle most after each oxygen production cycle.

Together with his colleagues, Palak Patel, a doctoral student at the Massachusetts Institute of Technology, devised an experiment molten regolite electrolysis systemto extract oxygen and metal from lunar soil.

“We are really seeing it from the point of view of ‘let’s try to minimize the number of replenishment missions,” he says.

When designing his system, Patel and his colleagues approached the problem described by Dr. Burke: that low gravity could prevent the detachment of oxygen bubbles that are formed in the electrodes. To counteract this, they used a “Sonicador”, which exploits bubbles with sound waves to evict them.

Patel says that future resource extraction machines on the moon could obtain iron, titanium or lithium of the regolito, for example. These materials could help astronauts who live on the moon manufacture 3D printed spare parts for lunar base or spare components for damaged spacecraft.

The usefulness of the lunar regolito does not end there. Patel points out that, in separate experiments, he has molten simulated regolito in a hard, dark and similar material.

She and her colleagues discovered how to turn this substance into hollow and strong bricks, which could be useful for building structures on the moon. an imposing black monolithsay. Why not?