Physical Address

304 North Cardinal St.

Dorchester Center, MA 02124

Physical Address

304 North Cardinal St.

Dorchester Center, MA 02124

All planetary warming greenhouse gases are released into the atmosphere, carbon dioxide The most important emission. Thus, experts claim that the fossils are dramatically reducing our fuel use, but the carbon dioxide (CO2) should actively produce the atmosphere. Carbon capture technology is generally expensive and / or energy intensive and requires carbon storage solutions.

Stanford University researchers now offered a surprisingly practical strategy: the rocks do it for us.

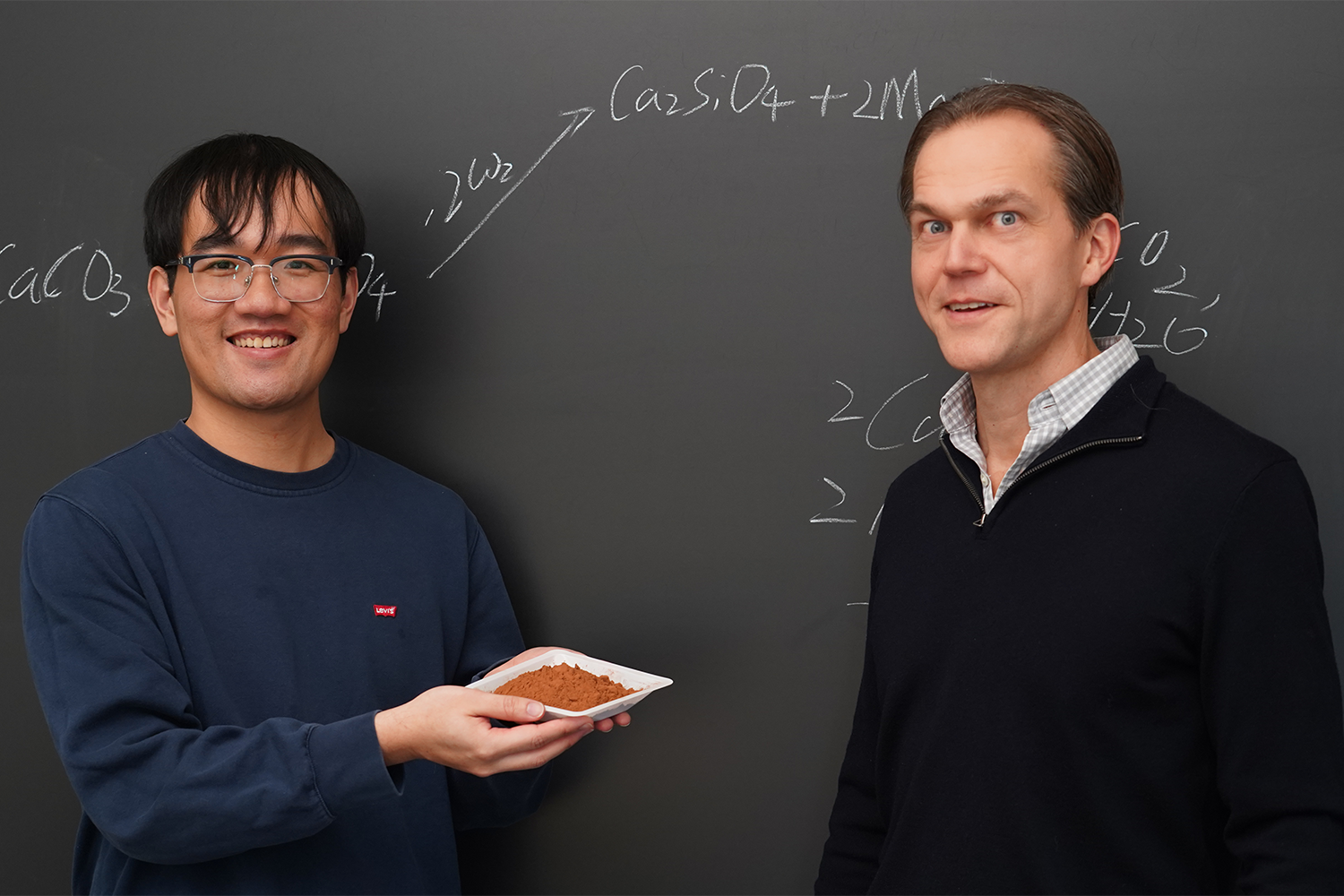

They don’t joke. Stanford chemists have developed a process that uses heat to transform the minerals to make Matthew Kanan and sleepy Chen, permanently absorb minerals. As a learn Published in the magazine on Wednesday NatureThe process is practical and inexpensive. In addition, Kanan and Chen were able to meet the needs of a common agricultural experience by hitting two birds with a stone.

“The Earth cannot be provided with inexhaustible minerals, which is able to produce CO2 from the atmosphere, but the canal of the canal, the great author of education. Stanford statement. “Our work solves this problem in a way we know the unique size.”

For decades, scientists have taught ways to accelerate the natural absorption of a CO2, which can take hundreds of thousands of years. Kanan and Chen, the silicates turned the code by turning the general slowly, transforming the gross slowly, converted into hot ventilators.

“We imagine a new chemistry to activate the inerti (chemical is not chemical) with a simple ion exchange reaction,” he said. Ions are atomic groups with atoms or electric loads. “We did not expect it to work at the same time.”

The Cannes and Chen were inspired by cement production, where the oven, or stove, limestone (sediment rock) are becoming a jet chemical combination called calcium oxide, then mixed with sand. Chemists repeated this process, but they turned off the sand for a material called a magnesium silicate. Magnesium consists of two minerals, which are silicate, heated, modified ions and magnesium oxide and calcium silicate.

“The process acts as a wheel,” he said. “You get a magnesium silicate in a jet mineral, calcium oxide and less inert and less inert and you create two jet minerals.”

Kanan and Chen wet calcium silicate and magnesium oxide to test the results were exposed to the airtime. They are carbonated minerals – the result of the air until the weeks.

“You can imagine the spread of magnesium oxide and calcium silicate to erase CO2 from the ambient air,” channel said. “An interesting application we have now tested adds them to agricultural lands.” This program can be practical for farmers who are excessively acidic, when it is acidic for farmers who add acid to carbonate, are called the harbor.

“To add our product, the alkaline of both mineral components would eliminate the need of elegance, which is alkaline (as opposed to the basic, acid),” he said. “In addition, such as calcium silicate, it can improve the production of plants in a form that the plants can improve the product and sustainability. There is a bonus for carbon extraction. “

About a ton of magnesium oxide and calcium silicate can evaluate CO2, which are less than half of the energy of a ton of CO2 and other carbon seizing technologies used in CO2 atmosphere.

This solution will require an effective level, every year will require millions of tons of magnesium oxide and calcium silicate. Nevertheless, if the calculations of magnesium silicate like Chen, Olivin or Serpentine are accurate, the atmosphere CO2 thrown by the whole person will be enough to eliminate it. In addition, silicates can be restored from mine waste (mining remains).

“The society has already realized how to produce billions of tons of cement year in the year, and cement furnaces last for decades,” he said. “If we use these learning and designs, there is an open way to how to get a carbon removal on a scale of laboratory discovery.”